News

Innovating Industry Safety: Choate Creates Advanced Stanchion Guardrail System

February 2, 2022

A concept designed to make railing safety simple.

Falls account for more than one-third (36.4%) of construction-related fatalities, and an area of susceptibility is balcony construction. Recognizing an opportunity for a new safety solution, Choate employee-owners designed and developed a brand-new system to eliminate this risk.

Previous Balcony Safety Systems

Guardrails on balcony builds required a period of time when the temporary railings are removed so the top layer of concrete for the balcony floor can be placed. While performing this work, workers need to be tethered or otherwise secured, as they are exposed to a fall risk before the permanent railings are installed. Though tethering and tie-offs present a potential for human error, as there are moments in between connecting tethers where workers need to move to another spot within the project space.

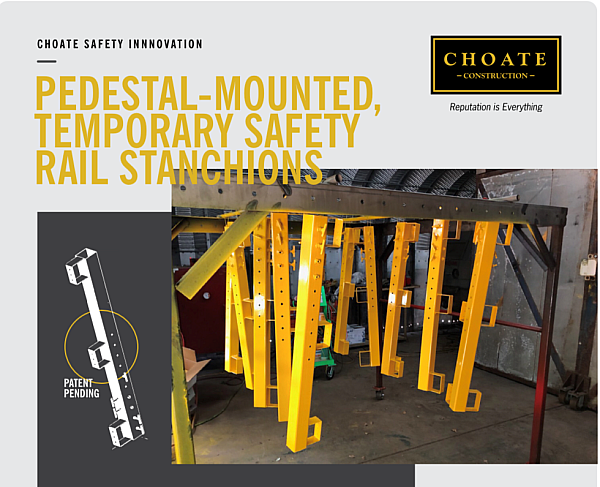

The Choate project team saw this possible exposure to risk as an opportunity for safety innovation. Having encountered similar railing concepts on previous jobs that are more permanently affixed to the structure, the team took it a step further, driven to bring something new to the industry that would be reusable from jobsite to jobsite. What first started as a sketch on a napkin evolved through Choate’s Virtual Design & Construction team into a model for the prototype. Now, the crafted railings, known as “Pedestal-Mounted Safety Rail Stanchions,” are able to withstand more than the 200lbs of weight required by the Department of Labor Occupational Health and Safety Administrations’ (OSHA) standards.

How It Works

In contrast to other temporary balcony railing systems, the Pedestal-Mounted Temporary Safety Rail Stanchions are designed to be reused from project to project. When the time comes to place the concrete slab on the balcony floor, the height of the stanchions can be adjusted to allow the concrete to be poured over the bases while the stanchions themselves remain in place—providing continued safety protection. Once the permanent railings are ready to be put in, the stanchions are removed, and the existing bases are incorporated into the permanent rails.

After withstanding tests, the team determined this railing system is able to withstand greater than the OSHA-required 200lbs.

Impact on Construction Community

The encouragement of continuous innovative thinking at Choate helps create safety solutions like the Pedestal-Mounted Temporary Safety Rail Stanchions that can be used on any jobsite. Sharing these solutions with the construction industry and working together to find new ways to innovate safety practices demonstrates the OneLife spirit in action, driving the potential to impact more than just Choate projects, but the industry as a whole.

This mentality plays a primary role in Choate’s numerous OSHA Partnerships, wherein project teams work alongside OSHA representatives on select projects to mitigate the potential for risk and identify opportunities for safety innovation. When we share knowledge, nationwide standards for construction safety can rise to significantly reduce the risk of injury across the industry.