Preconstruction Expertise

Building Better from the Start

Before a shovel ever hits the ground, the project vision, expectations, and definitions of success are defined in the preconstruction phase.

Ready and equipped to act as a resource every step of the way, Choate offers an arsenal of tools – and an army of experts – to ensure we deliver the maximum return on your investment and your vision.

F E A T U R E D | Beni Palmer (left), Senior Preconstruction Manager, and Mark Hughes (right), Choate Charlotte Interiors Division Manager, accept the ENR Southeast “Best Project – Interior Construction/Tenant Improvement” award for the 375,000-SF renovation of Fiserv’s Atlanta-area operations center.

Whether your building program is fully defined or in its infancy stages, Choate’s dedicated in-house preconstruction team will walk beside you throughout the entire preconstruction process.

Laying a Solid Foundation

When does the preconstruction process begin?

For us, preferably long before pencils are sharpened and formal pricing exercises occur.

When brought in early, we can be a valuable resource. Services like in-house site selection support and conceptual site layout, laser scan analysis of existing spaces, and thoughtful constructability studies can support the development of the most effective building strategy right from the start.

Our goal? To ensure that even conceptual numbers are rooted in smart planning and provide a solid foundation to build upon.

Smart progression...

Taking a conceptual price and navigating it through design development requires collaboration, creativity, and an eye towards the future. After all, our job at this stage is to provide the lowest possible cost for your given level of design and quality, all while balancing the market fluctuations occurring throughout the process.

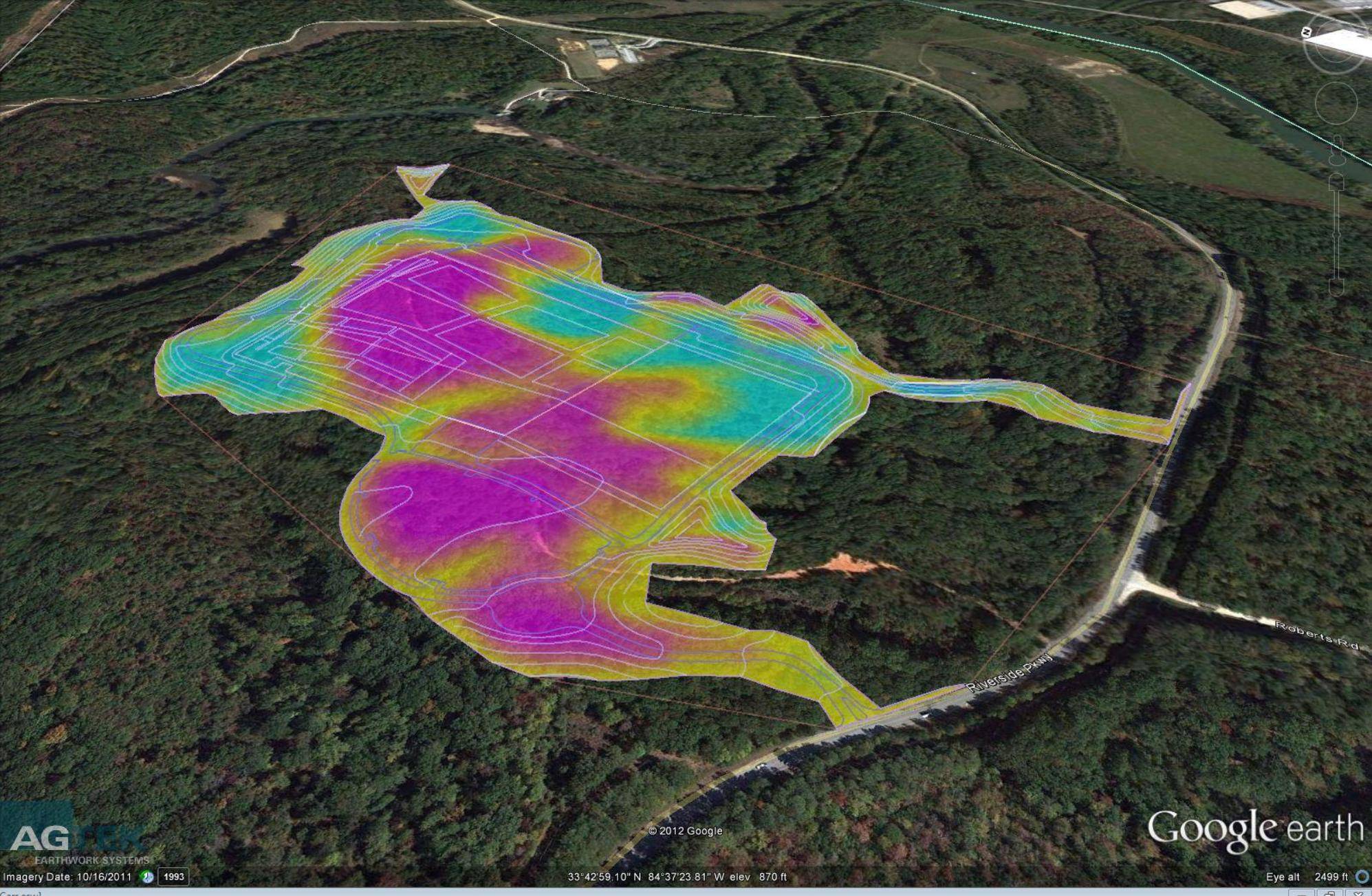

F E A T U R E D | Armed with AGTEK and SITEOPS software, the preconstruction team at Choate produces cutting-edge 3D and 4D models to thoroughly examine a site. In Design-Build and preliminary budgeting scenarios on undesigned sites, SITEOPS provides an unmatched efficiency and “broad brush” picture for our clients. AGTEK, however, shines on fully designed sites when geotechnical information is available, providing value engineering data to help the engineering team with redesign.

...And an Integrative Approach

As we progress through pricing stages, Choate will ensure:

-

- Continual market trend analysis occurs, preventing surprises and accommodating long-lead items

- Instant response to design developments with real-time cost data

- Major trades are involved in a design-assist manner

- Results-driven virtual construction implementation

- Life-cycle costing

- On-screen take-off

- Real-time cost estimating

- Site selection analysis

- Smart value optimization to enhance rather than detract

- Subcontractor selection based on proven prequalifications

- Model-based quantity surveys

- Sustainability cost analysis

- Value enhancement analysis

Throughout it all, design intent is consistently balanced with cost, feasibility, and constructability to result in construction efficiencies and optimized values.

The preconstruction phase sets the foundation of a valuable partnership. How does Choate provide a better building experience?Click to find out.

Scheduling Starts Here

IN ADDITION TO COST, SCHEDULE DEVELOPMENT ALSO STARTS IN THE PRECONSTRUCTION PHASE.Fast-track opportunities are identified early; cost and resource allocations are proactively loaded into traditional construction timelines. There are no stones left unturned and no worst-case scenarios when boots hit the ground.

SPEAKING OF BOOTS...Thanks to an integrated approach, there are no hard lines between preconstruction and construction – simply a seamless transition.

"Your commitment to our team for budget, schedule, and quality control in a tough, complex construction environment were challenges you overcame with diligence and class that would make any developer proud."

RICHARD PEASE, PRESIDENT, BREK MANAGEMENT, INC.

Learn more about our construction servicesAre you prequalified to work with Choate?

Subcontractor Registration

If you are a new vendor interested in working with Choate, we encourage you to visit our Subcontractor Portal and fill out our Subcontractor Registration form.

A building is only as good as its foundation. When choosing a contractor, carefully consider the preconstruction approach.

Isn’t Preconstruction simply about determining the price of the project?

PRECONSTRUCTION IS SO MUCH MORE THAN THE DOLLARS AND CENTS OF A JOB.

Choate’s integrated preconstruction process is focused on smoothing a project’s path prior to mobilization and eliminating challenges before they become costly in-field conflicts. This phase is also the perfect opportunity to address a broad range of concerns, such as:

-

- Permitting, governmental involvement

- Value-enhancement opportunities

- Constructability reviews

- Building material selection

- Schedule challenges

- Site selection

- Site requirements

Equipping our clients with the data to make smart, financially sound decisions when decisions matter most – that’s the ultimate preconstruction benefit.

What does the preconstruction process entail?

OUR PRECONSTRUCTION PROCESS IS DETAILED, HIGHLY INTEGRATED, AND COLLABORATIVE.

We begin by asking, “What is success?” This stakeholder-driven question provides the necessary answers for our preconstruction team to outline all primary project objectives.

From there, we assess next steps and determine the level of deliverables required to move your project to a predetermined accuracy point with regard to schedule and cost. Constructability is assessed, quotes analyzed, and opportunities for value optimization are identified. Construction technology, such as 3D laser scanning, 4D construction sequence planning, and building information modeling provide additional data-driven guidance.

Simply, the preconstruction process entails ensuring every “t” is crossed, “i” dotted, and design intent is balanced with your project vision, budget, and schedule.

Site selection can be as important as the building itself. Can my contractor help with that process?

The process of identifying, evaluating, and selecting an optimal site can present a myriad challenges for owners.

How do you know if a potential site is prime property, a diamond in the rough, or a money pit of surprises?

Armed with innovative takeoff and modeling technology, Choate’s preconstruction and virtual construction teams are able to dig deep into your site well before mobilization. Through SITEOPS conceptual design software and the production of 3D & 4D models, we can thoroughly examine site conditions, topography, grading, and piping layouts to determine optimal building positioning.

AGTEK’s Sitework 4D allows us to perform accurate on-screen takeoff, GPS modeling, and mobile control of earthwork. These tools ensure dollars go further and efficient grading occurs.

Together, these visualizations of data provide a more thorough understanding of the jobsite, a budget with a higher degree of solidity, and a streamlined schedule with unquestionable integrity. This is how laying a solid foundation begins.

What actions are taken to ensure the most qualified, reliable subcontractors are selected?

As a faithful steward of your investment, we make the selection of the right trade partners one of our highest priorities.

We look for like-minded, competitive firms who are safe, financially stable, responsive and have a proven performance record.

A checks-and-balances management approach, which includes subcontractor prequalification, ensures active firms are operating at levels as expected from safety, manpower, schedule, quality, and budget perspectives. It takes much more than equipment and hard work to transform an idea into a tangible reality – it takes a proven team.

What about value enhancements?

Rolex visions on a Casio budget? Or simply a desire for maximum return on investment – the ability to balance desired design with a project’s sometimes limited budget takes diligence and ingenuity.

Often called “value enhancement,” this is the process by which alternative means, methods and materials are investigated and compared against both the initial construction costs and future costs such as life cycle and operation/maintenance costs.

Throughout the design process, we review the constructability of the project for maximum optimization. We like to get the team thinking outside the box.

-

- Extensive structural comparisons, including cast-in-place concrete, structural steel, precast concrete, tilt wall, etc.

- Cost analysis of prefabricated materials vs. in-place construction

- Extensive foundation design analysis, using AGTEK and SITEOPS

No matter the project, a creative approach enables us to enhance the project, not simply engineer out original intentions. And that is what good stewards do.